-

Techkon DENS

Highlights

- The new Techkon DENS unifies three devices in one. It is a color reflection densitometer for CMYK color prints, a film transmission densitometer and a high-precision illuminated magnifying glass for the visual control of printing results.

- The DENS indicates densities, dot area and gray balance clearly legible on a large color display. Automatic color and gray balance detection speeds up the measuring.

-

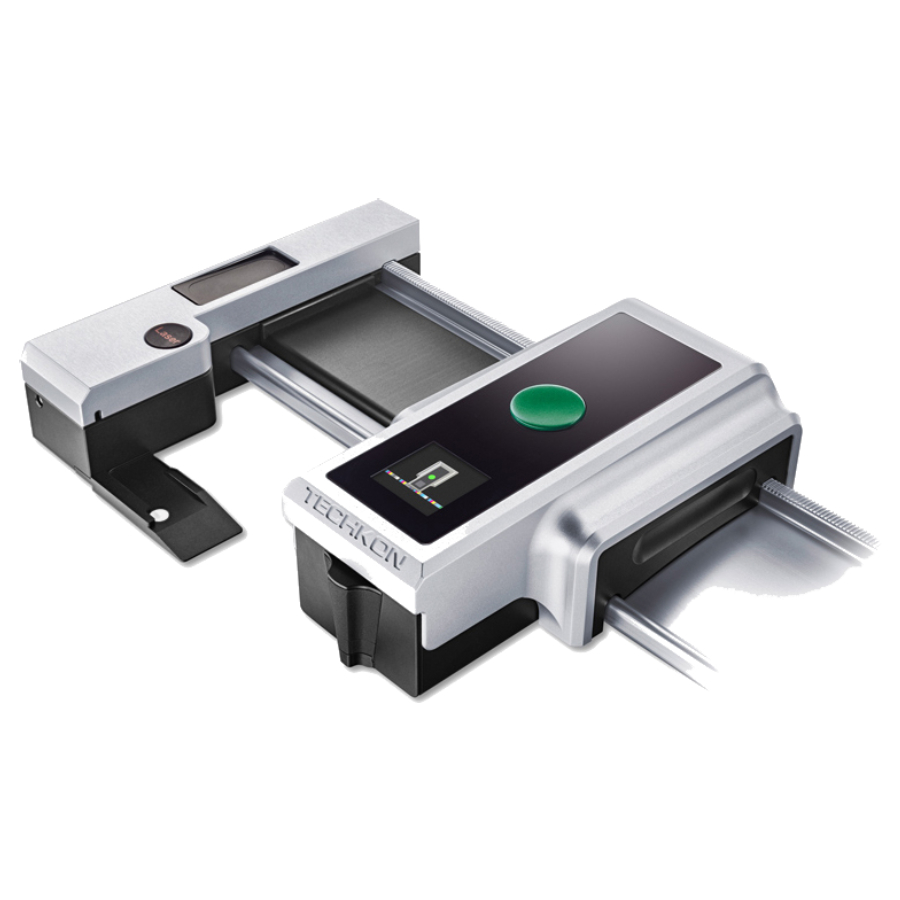

Spectro Plate

Highlights

- The Techkon SpectroPlate is a high resolution digital microscope that measures dot percentage, screen angles, lines per inch/cm, dot gain and AM, FM or Hybrid Screens of traditional offset or process-less, chemistry-free printing plates.

- The SpectroPlate is extremely fast. A single measurement takes just 1 second.

- Measures All Types of Plate Media

Conventional & chemistry free plates, polyester and paper. - Measures All Types of Screening

Including AM, FM and Hybrid form low to high resolutions. - Long Lasting Battery

Up to 10,000 measurements per charge. - QC Software Included

Build transfer curves and examine dot image captures. - Ability to Measure Without Computer Connection

Measure, save and view up to 250 sample measurements without the need to be connected to a computer.

-

Scanning Spectrophotometer

Highlights

- Fast

The SpectroJet, a “spectrophotometer on wheels”, automatically measures density and color values of process and spot colors, and simultaneously transfers the measurement data to a PC within seconds. - Easy to Use

The device is simply guided by hand along color test patches,with tracking wheels to ensure a straight run. - Versatile

The instrument can be used for automatic scanning or as a hand-held device for “spot check” measurements

-

Auto Scanning Spectrophotometer

Highlights

- Fast

The SpectroDrive scans press sheet color bars in a matter of seconds while simultaneously sending spectral and density measurement data to a PC running the Techkon Expresso software. Scan a 40? press sheet in less than 8 seconds. - Accurate

The measured density and color information is displayed with suggested density changes for more accurate color. The spectral color engine delivers unbeatable measurement accuracy and consistency over time. - Versatile

The SpectroDrive can be used for automatic scanning or as a hand-held device for “spot check” measurements.

2017 New Generation Features

- Measurement Modes

M0/M1/M2/M3 for compliance with G7 and new ISO standards. - Screen on Scanner

Displays color values, density, battery/wireless status, and shows current measurement conditions. - Laser Guide

Verify alignment of color bar more easily before scanning. - More Rugged

Solid aluminum casing, wireless charger, improved wheel design.

-

SPECTRO-DENSITOMETER

Highlights

- The fastest & easiest way to control color and density in the pressroom.

- Techkon’s SpectroDens delivers unbeatable measurement accuracy and repeatability over time. And it’s the most ergonomic device on the market. That’s why operators consistently prefer the SpectroDens to the cumbersome, slow, clamshell style devices they have used in the past.

Six reasons you need the Techkon SpectroDens

- Standards complicancy: The SpectroDens includes full support for ISO and G7® methodologies, and fulfills M0, M1, M2, M3 measuring conditions in accordance to ISO 13655.

- Speed: The innovative measurement head allows a single spot measurement approximately every 1 second while the patented, side-aperture design lets you easily position the optics over the desired measurement location for even faster operation.

- Accuracy: The high-resolution spectral engine enables spectral sampling in 10 nm intervals from 400 nm to 700 nm

- Versatility: Seamlessly switch between spot measurements and color bar scanning up to 43-inches long, with the push of a button, and without the need for additional accessories.

- Ergonomics: As well as being comfortable and easy to use, no moving parts means the solid state spectral engine can deliver unbeatable measurement accuracy and repeatability over time

- 2018 Intertech Award winner: The judges liked its unique “combination of super-fast measurement speeds, heightened intelligence, and a built-in mode for color bar scanning” and concluded they “foresee SpectroDens4 becoming the spectrophotometer of choice in many pressrooms.”